Plastic Injection Molding - what is it?

Injection molding is a technological process widely used in the production of plastic products. It involves the plasticization (heating) of plastic granules, followed by injecting them under high pressure into a mold that gives the material the desired shape. After cooling and solidifying the material, the finished component is removed from the mold.

This process is highly efficient and allows for the production of precise and repeatable parts in large quantities. Injection molding is used in many industries, from automotive to electronics, as well as for manufacturing everyday items such as packaging and toys.

Contact Us! Find out how much production with plastics at M I K will cost you!

Get a quote

Why is it worth using injection molding technology for plastics?

Injection molding of plastics provides precision and repeatability, allowing for the production of complex components with uniform dimensions. This process is efficient and enables rapid manufacturing of products at a low unit cost.

With design flexibility, various materials can be used, including modified ones, allowing for the adjustment of product properties to meet structural requirements. Automation minimizes labor costs, while hot runner systems and recycling increase efficiency.

Although mold costs are high, injection molding is cost-effective for large series, making it popular across many industries.

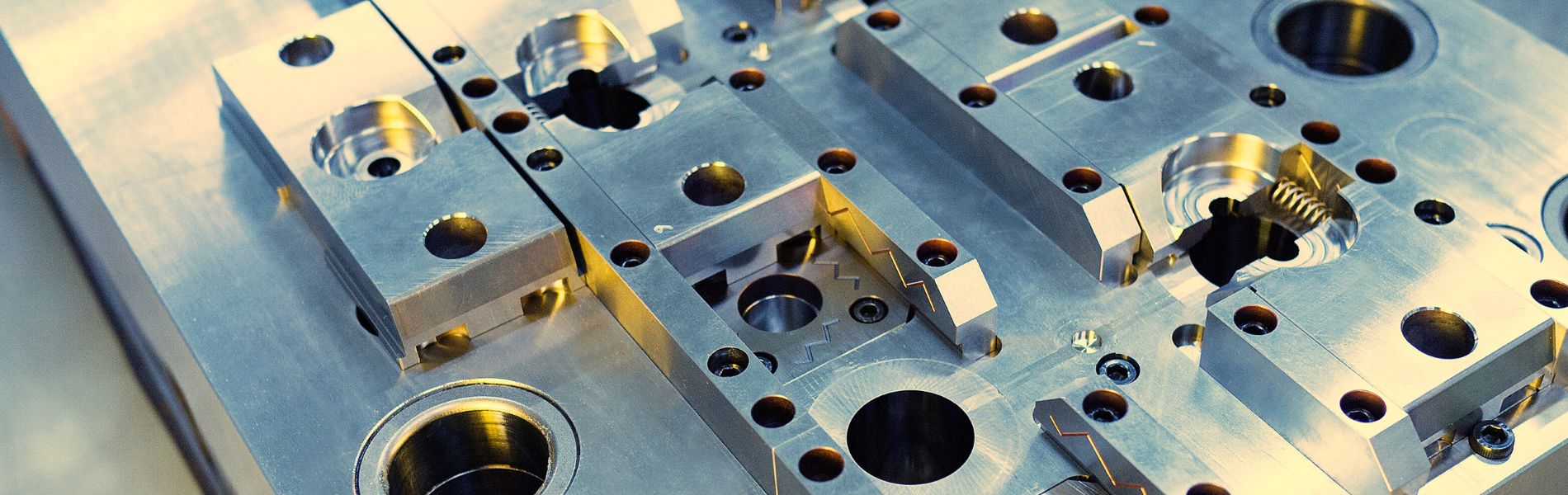

Injection Mold - Key Information

How does the injection molding process work?

The injection molding process begins with the dosing of granules into the hopper of the injection molding machine, where they are fed into a cylinder equipped with heaters. Here, the material is gradually heated until it becomes plastic, and the rotating screw pushes and simultaneously mixes the material, heating it to a liquid state. Once the material reaches the appropriate temperature, the screw acts as a piston, injecting the liquid plastic under high pressure into the mold, which shapes the product. The mold consists of two parts – the cavity and the core – which create a recess with the desired shape of the part.

After the injection of the material, cooling occurs, during which the material hardens, taking on its final form. The cooling time depends on the thickness and type of plastic. Once the plastic has hardened, the mold opens, and the finished part is removed using ejectors. The production cycle can immediately repeat, starting a new injection molding process. After removal from the mold, parts may require additional processing, such as removing excess material or assembly.

Injection Molding Outsourcing – What Do You Save?

If you decide to outsource injection molding production to our company, you will avoid many costs associated with investing in infrastructure and equipment. Here are the main costs you won’t incur:

- No Investment in Injection Molding Machines

You don’t have to purchase expensive injection molding machines, which can cost hundreds of thousands of złotys. We have a modern machinery park ready to work, allowing you to save on high purchase and maintenance costs of equipment. - Full Automation and Additional Equipment

We handle all production automation – from robots, to conveyors, to cooling devices. This means you don’t need to invest in additional equipment, as we provide comprehensive solutions that maximize efficiency. - Maintenance and Servicing of Machines and Molds

You don’t have to worry about the maintenance of molds or machines – regular servicing and upkeep are on us. We guarantee that each mold is well-maintained, which translates to a longer lifespan and trouble-free production. - Optimization and Quick Production Implementation

We ensure full calibration and optimization of the injection process, which shortens the production implementation time. Our experienced team of technicians will take care of the correct machine settings, minimizing costs related to trials and tests, while also ensuring a faster production start-up time.

Get to know our machinery park and the technological processes we use in production!

List of machines

Support in the Investment Process

Outsourcing production is a challenging undertaking that we can help you prepare for. We coordinate the entire technology transfer process and optimize its costs.

See moreAssembly

Is your product composed of more than one component? Utilize our assembly technologies for component assemblies, incorporating processes such as soldering, thermal welding, riveting, screwing, or gluing.

See morePackaging

We deliver products in the format your organization requires. We carry out packaging, packing, and labeling according to the specified requirements.

See moreStorage

We offer a full range of storage services. We provide temporary storage, short-term, and long-term storage in appropriately tailored conditions.

See moreLet’s talk about what your company needs.

We will help you optimize the production costs of plastic products. Whether you’re looking to relocate existing production or start a new one – we provide support at every stage. Fill out the form so we can discuss your project, provide a quote, and then outline the proposed steps for moving forward.